KVTC Traveling Column VMC Series

Product Highlights

The Kent CNC Traveling Column Type Vertical Machining Centers combine proven machine design with advance technology in control and manufacturing. Reliability and performance make this series a favorite among demanding job shops and in-house productions alike. Traveling column milling gives you more efficiency and power by having the XYZ movements on the column and a fixed large table. This setup is beneficial especially if the job requires machining multiple workpieces at a time, which can vastly reduce your load/unload time. In addition, the heavy cutting spindle and rigid machine structure enable higher milling efficiency with better finish and longer tool life – resulting in greater productivity and profitability all around. Lastly, our high speed traveling column center VMCs are equipped with CAT, ISO, and DIN 40/50 Taper options with around 10000 RPM in spindle speed or more.

The Kent CNC Track Record of Reliability

With over 18,000 machine tools sold worldwide since 1979, Kent CNC Traveling Column VMCs are proven to increase productivity, delivering reliable and profitable performance. For other capacity requirements, please see our Linear Way 3-Axis VMC, Heavy Duty High Speed VMC and Double Column VMC.

Large working capacity of up to 126” x 28” x 24” travels and 138” x 24” table

Powerful 25HP servo spindle motor with up to 12,000 RPM with spindle chiller system

Fanuc AICC-NANO high speed contour control

Fanuc “i” series high torque dual wound high/low spindle motor

Fanuc data server and ethernet

Fanuc 0i-MD control w/10.4” LCD color monitor & solid graphics

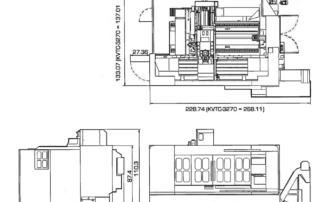

| KVTC-2260 | KVTC-3270 | |

|---|---|---|

| X Axis Travel | 87″ | 126″ |

| Y Axis Travel | 25″ | 29″ |

| Z Axis Travel | 25″ | 25″ |

| Spindle Nose to Table | 28″ | 31″ |

| Spindle Center to Column | 4.8″ – 29″ | |

| Table Dimension | 98.4″ x 23.6″ | 137.8″ x 23.6″ |

| T-Slot | 0.71″ x 5 x 4.92″ | |

| Table Height From Floor | 33″ | 35″ |

| Table Load Capacity | 33″ | 35″ |

| Spindle Nose to Table | BT40 / CAT40 / DIN40 (Opt.BT50 / CAT50 / DIN50) | |

| Spindle RPM | BT40: 75 – 10000 RPM (Opt. BT50: 75 -6000 RPM) | |

| Main Motor | BT40: 15/20HP (Opt. BT50: 20/25 HP) | |

| ATC Magazine for Arm Type | 24 / 32 / 40 | |

| Tool Diameter | BT40: 3″ (Opt. BT50: 4.9″) | |

| Tool Length | BT40: 11.81″ (Opt. BT50: 13.78″) | |

| Tool Weight | BT40: 15 lbs (Opt. BT50: 33 lbs) | |

| Rapid Traverse | 1417 ipm | |

| Cutting Feed | 0.039″ – 590.55″ | |

| Positioning | ± 0.003 mm | |

| Repeatability | ± 0.002 mm | |

| Coolant System | 580 W | |

| Lubrication Sustem | 25 W | |

| Air Pressire | 85 PSI | |

| Machine Weight | 31305 lbs | 38581 lbs |

| Floor Space | 160″ x 229″ x 118″ | 164″ x 268″ x 118″ |

| CNC Control | Fanuc 0i-MD | |

Standard Equipment

- Spindle Chiller

- External MPG

- M30 Auto Power Off

- Chip Conveyor

- M-Code Air Blast

- Air Condition for Electrical Box

- Auto Lubrication System

- Oil Skimmer

- Coolant System

- Leveling Pads and Screws

- Tools & Toolbox

- Water/Air Gun

- Rigid Tapping

- Halogen Lamp

- Alarm Tower

- Full Enclosure Cover

- Electrical/Operation Manual

Accessories

- 4th/5th Axis Rotary Table

- 12k RPM Spindle

- Auto Tool Length

- Coolant Through Spindle

- CE Electrical Box

- Optical Scale